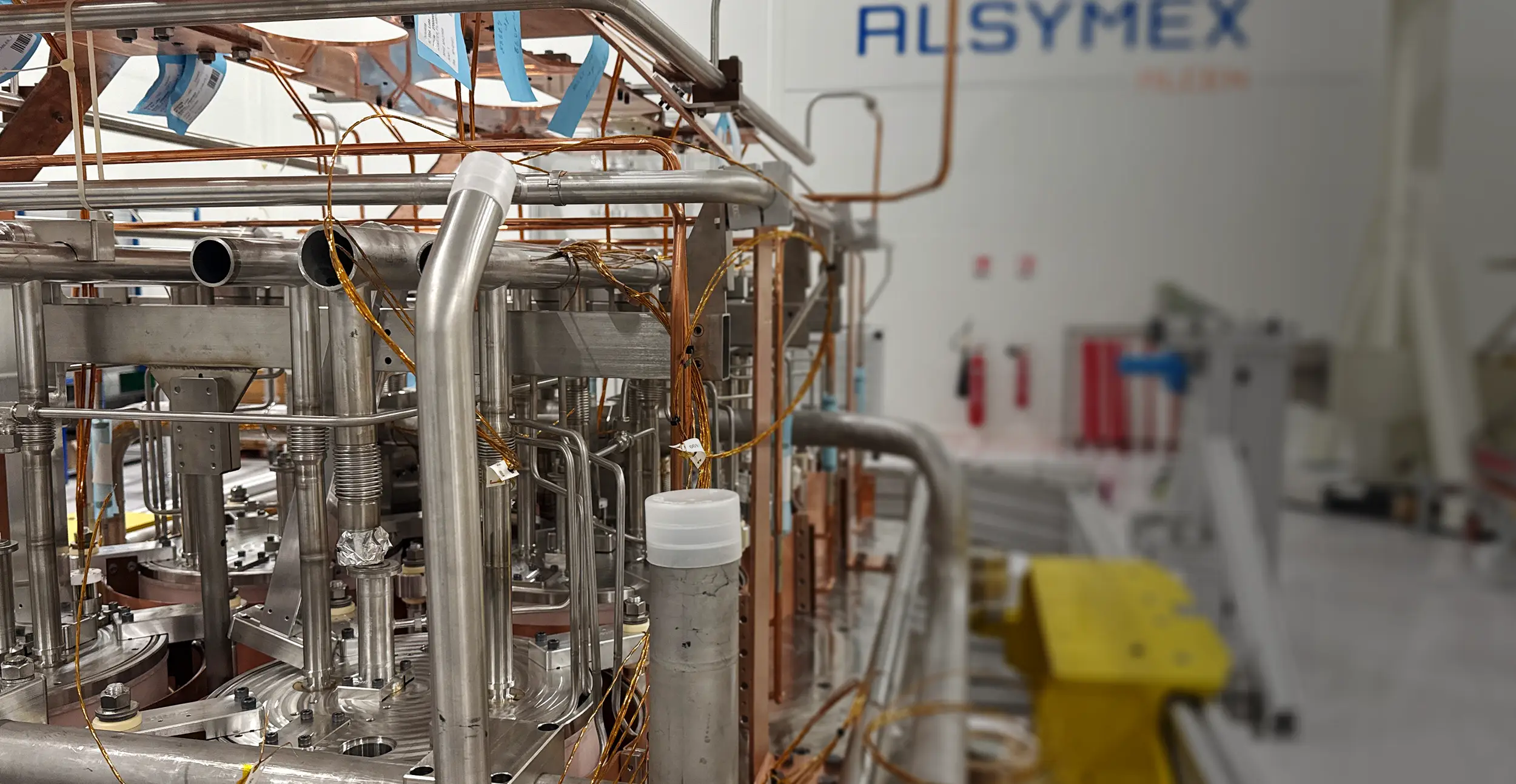

ALSYMEX Expertise

High-Precision Machining of Medium to Large Components

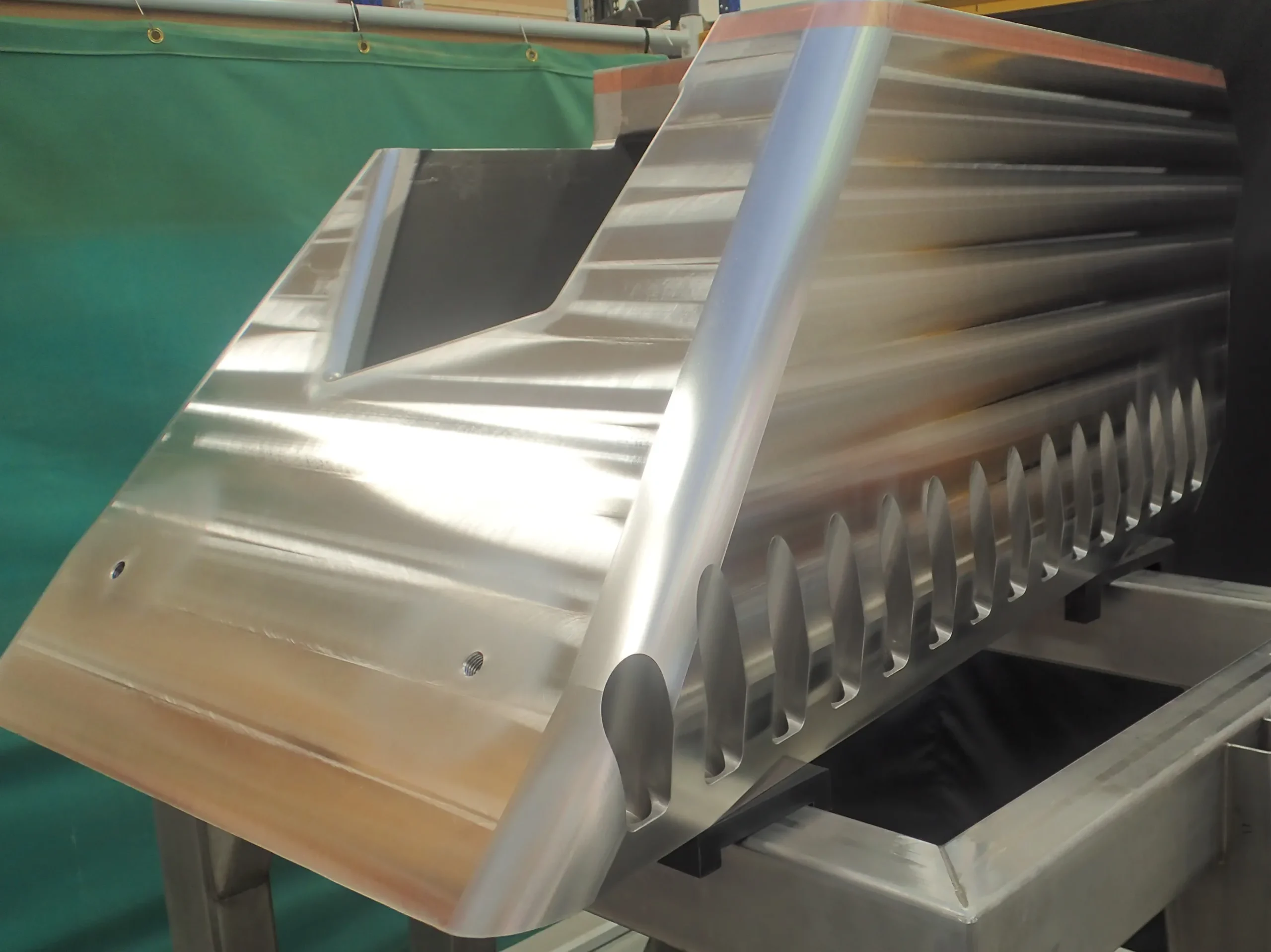

ALSYMEX masters the techniques and constraints related to high precision machining of large dimension mechanical components and infrastructures. This operation is done in a special air-conditioned workshop, maintaining the high stability of parts throughout the entire machining process. Main characteristics are:

- Workshop surface: 3,000 m2

- Temperature: 20°C ± 1°C

- Lifting capacities: 30 tons (hook height: 12 m)

- Milling capacities: up to 10 m (length) × 3 m (width) × 3 m (height)

- Turning capacities: up to 5 m diameter, 3.5 m high

- Accuracy of a few hundredths of a millimeter

- Materials commonly machined: aluminum, copper, stainless steel, complex alloys

- Geometrical and dimensional control capacities: Coordinate Measuring Machines up to 3 m (length) × 2 m (width) × 1.6 m (height); laser trackers

The expertise and means of ALSYMEX make it possible to meet the most demanding specifications in the Aerospace, Defense, Large Scientific Instruments and Nuclear sectors.

Reference in High-Precision Machining of Medium to Large Components

ALSYMEX Expertise

Welding Engineering

ALSYMEX masters a wide range of special manufacturing process, often combined on a single component to meet the most demanding technical and environmental requirements.

This unique ability allows ALSYMEX to design, qualify and produce complex assemblies that guarantee performance, reliability and durability, even under extreme conditions.

Among such processes, ALSYMEX integrates and controls several highly accurate welding techniques such as TIG (automatic, orbital, manual), laser or electron beam welding on a wide set of material and geometries.

In order to successfully carry out the works while meeting its clients’requirements, ALSYMEX has a portfolio of several hundred of welding procedure qualifications and relies on an extensive team of experts including International Welding Engineers (IWE), International Welding Specialists (IWS), International Welding Technicians (IWT) and qualified welders. ALSYMEX also benefits from in-house welding equipment (Automatic TIG robots, laser welding machines and an electron beam machine).

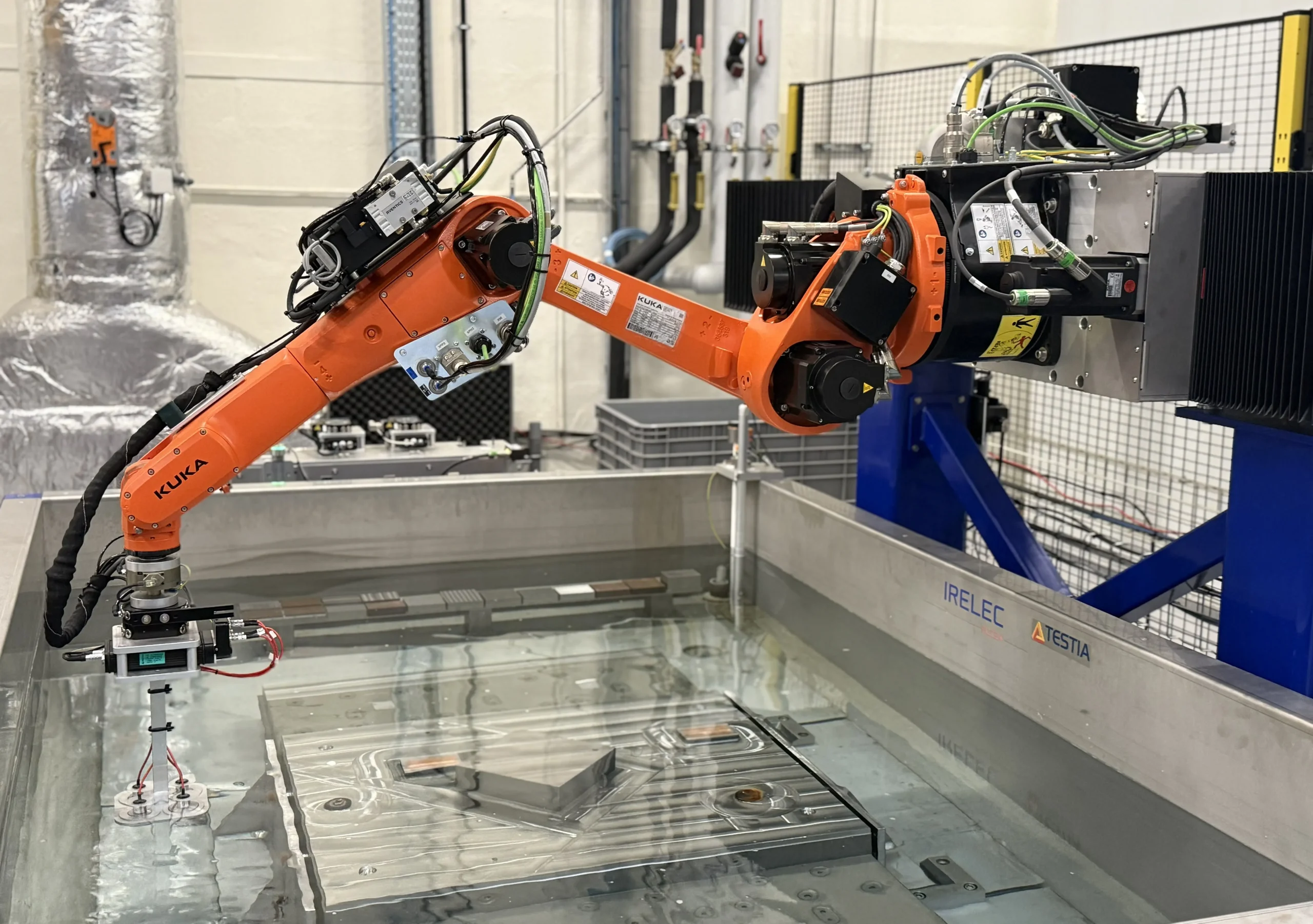

Welding or Special Process activities are carried out in close connection with ALSYMEX NDT (Non Destructive Test) specialists. ALSYMEX has indeed a recognized expertize in Non Destructive Examinations, including leak testing (LT), penetrant testing (PT), visual inspection (VT/VTI), ultrasonic testing (UT), radiographic testing (RT), through its team of certified levels 2 & 3 inspectors according to EN ISO 9712.

In collaboration with academic partners, ALSYMEX is also leading challenging R&D programs that aims at developing and qualifying innovative techniques such as Laser Metal Deposition (LMD) technics for the obtention of thin structures in forged-like quality stainless steel or titanium alloys or tele-operated welding solutions.

Reference in Welding Engineering

ALSYMEX Expertise

Hot Isostatic Pressing

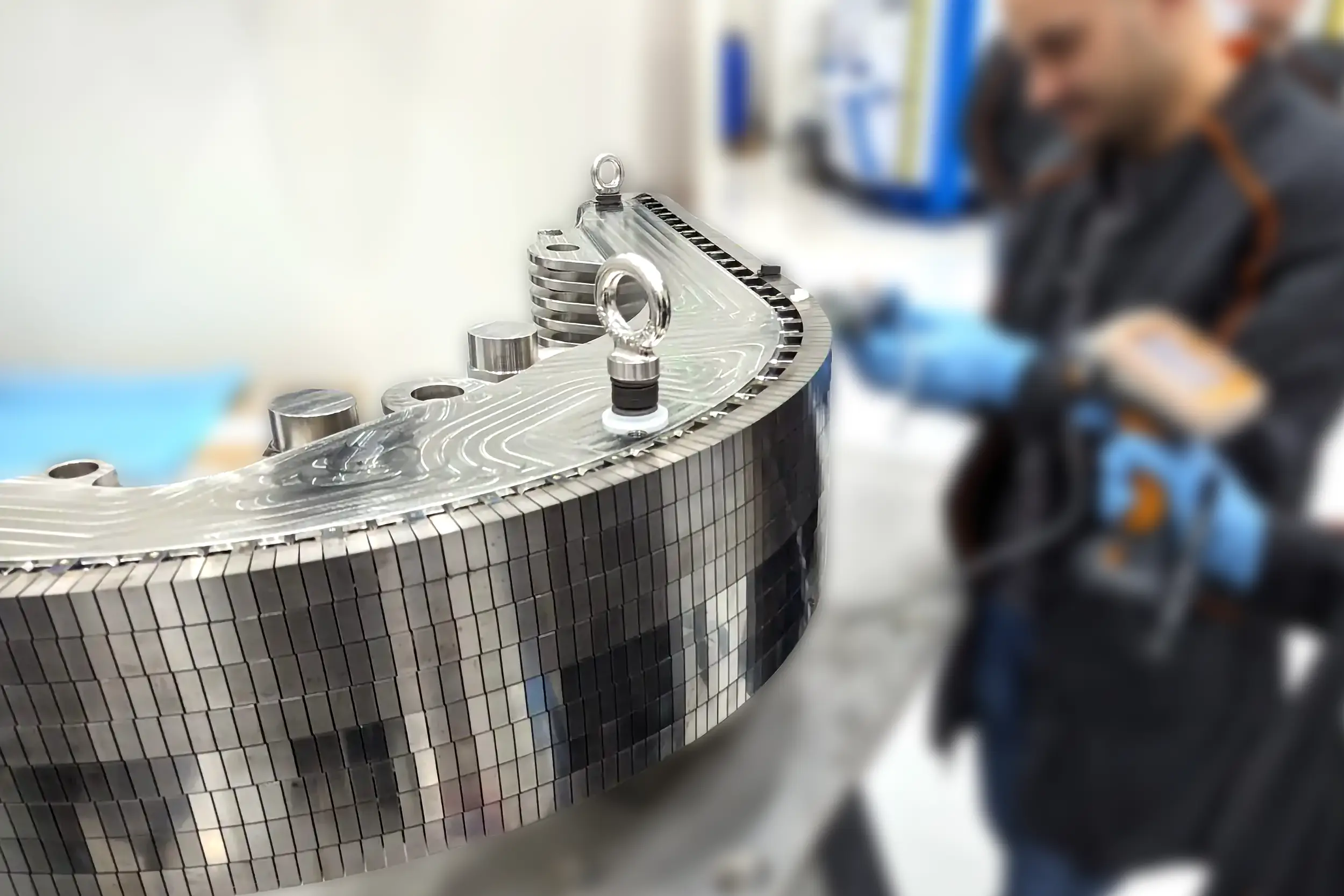

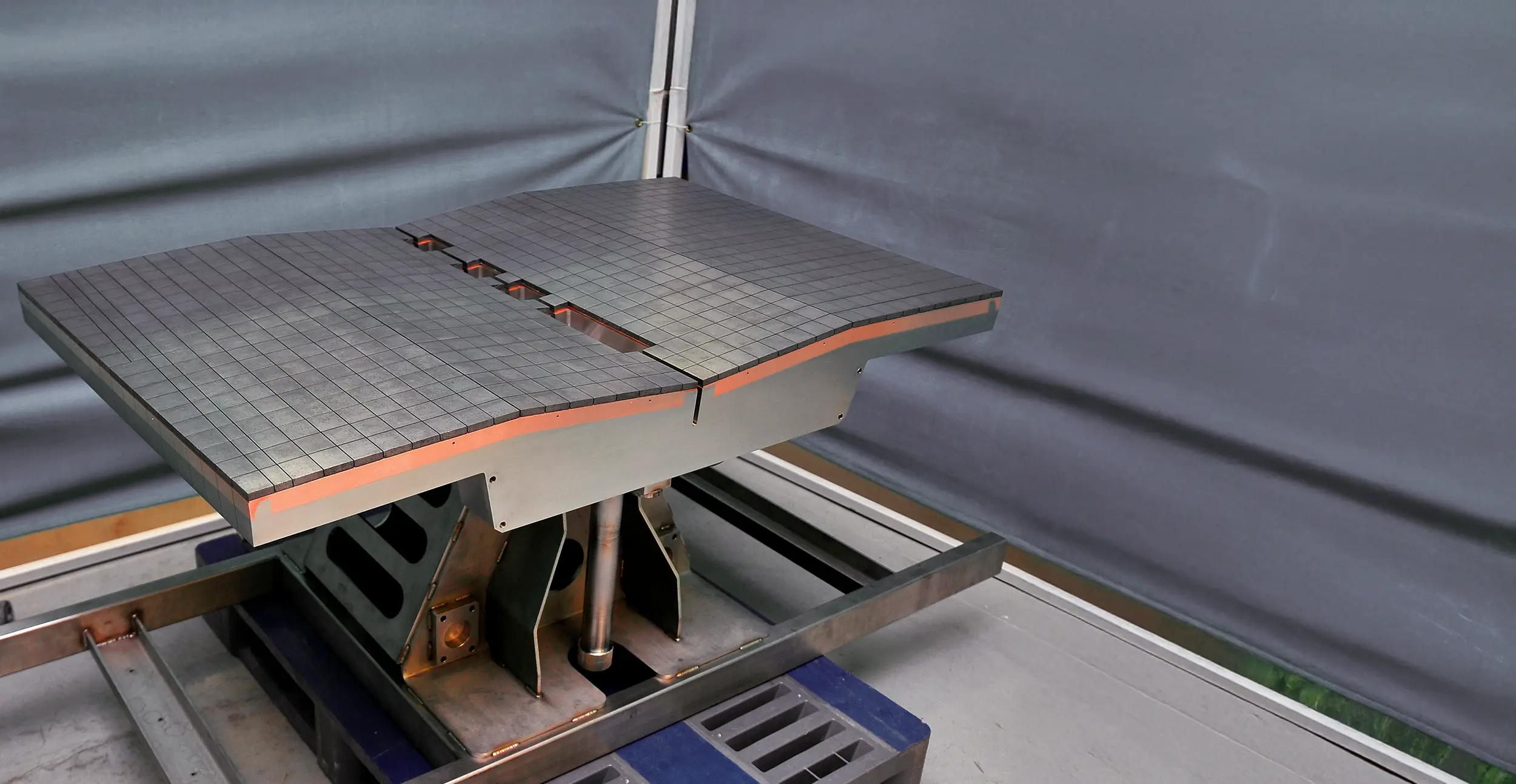

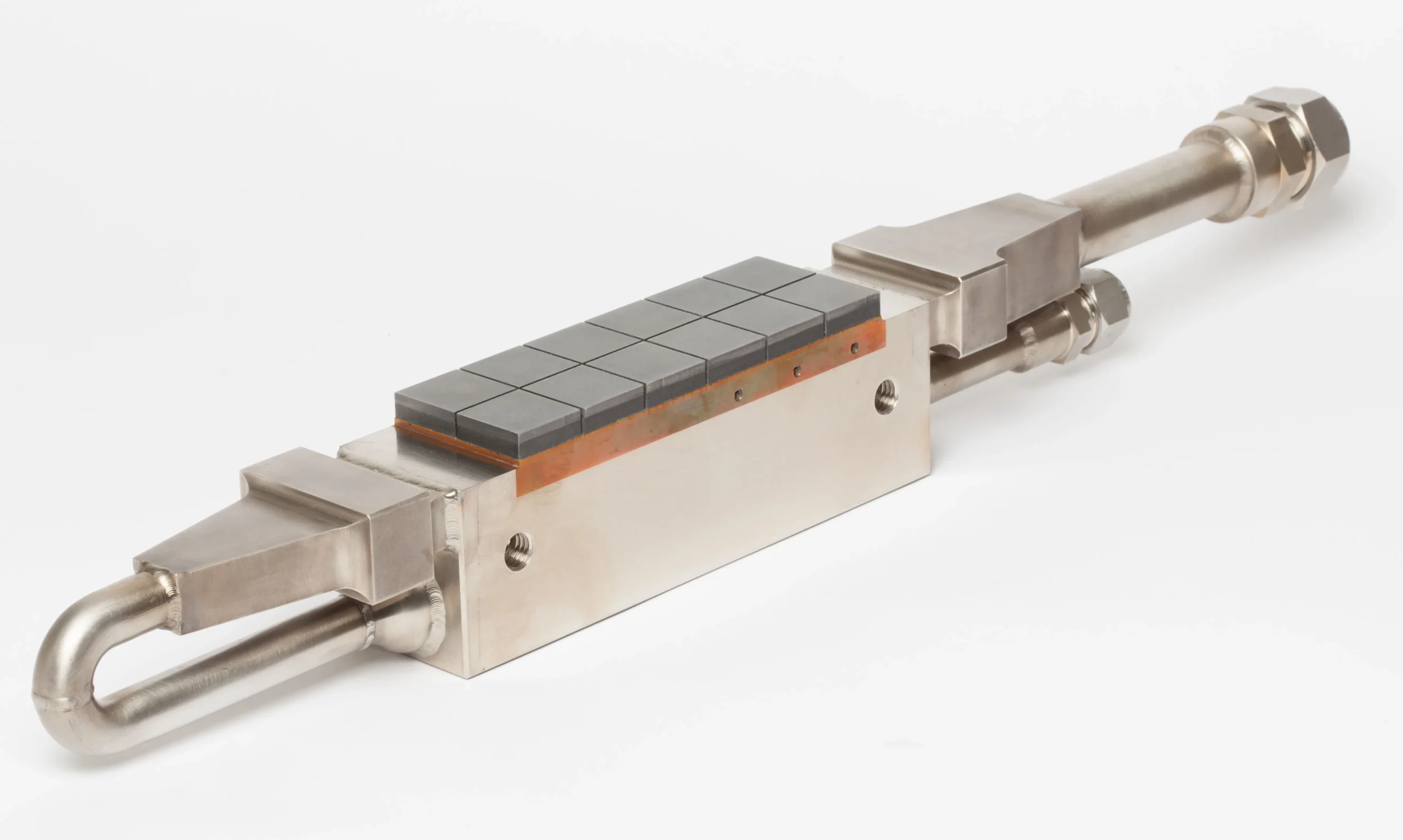

Diffusion bonding assisted by Hot Isostatic Pressing (HIP) is a solid-state joining process used to create strong bonds between similar or dissimilar materials.

It involves applying high temperature and pressure simultaneously, which enhances the diffusion of atoms across the interface of the materials being bonded. This results in a metallurgical bond with excellent mechanical properties and uniformity throughout the joint.

Given the remarkable thermal and mechanical properties it allows, diffusion bonding assisted by HIP is widely used in Nuclear Fusion applications especially for plasma facing components.

In the frame of the ITER project and through components such as First Walls, Divertors or TBMs, ALSYMEX has developed a strong expertise in diffusion bonding from development to design quand qualification activities.

Reference in Hot Isostatic Pressing

ALSYMEX Expertise

Equipment Made from Beryllium

At ALSYMEX has developed unique expertise in the manufacturing and integration of mechanical components made from Beryllium and Beryllium alloys — materials known for their exceptional lightness, mechanical strength, and thermal resistance.

ALSYMEX’s expertise combines high-precision machining, strict contamination control, and rigorous safety procedures to deliver components that meet the world’s most demanding industrial and scientific standards.

-

Ultra-Precision Machining

Accuracy of a few micrometres and hundredths of a millimetre, for small to medium-sized components. -

Post-Machining Surface Treatment

Chemical etching, precision cleaning, and surface integrity control (anti-smearing) to ensure flawless finish and performance. -

Controlled Environments

Operations performed in specially conditioned workshops, equivalent to cleanrooms, to maintain cleanliness and precision. -

Regulatory & Environmental Compliance

Full adherence to environmental and regulatory standards governing Beryllium use. -

Health & Safety Commitment

Implementation of strict HSE protocols to protect all personnel involved in Beryllium machining.

Thanks to its expertise, Alsymex serves industries and research sectors where materials must be both lightweight and exceptionally resistant, mechanically and thermally.

Typical applications include:

- Scientific instruments

- Aerospace components

- Defense systems

- High-performance optical assemblies

Reference in Equipment Made from Beryllium

ALSYMEX Expertise

Safety Control-Command

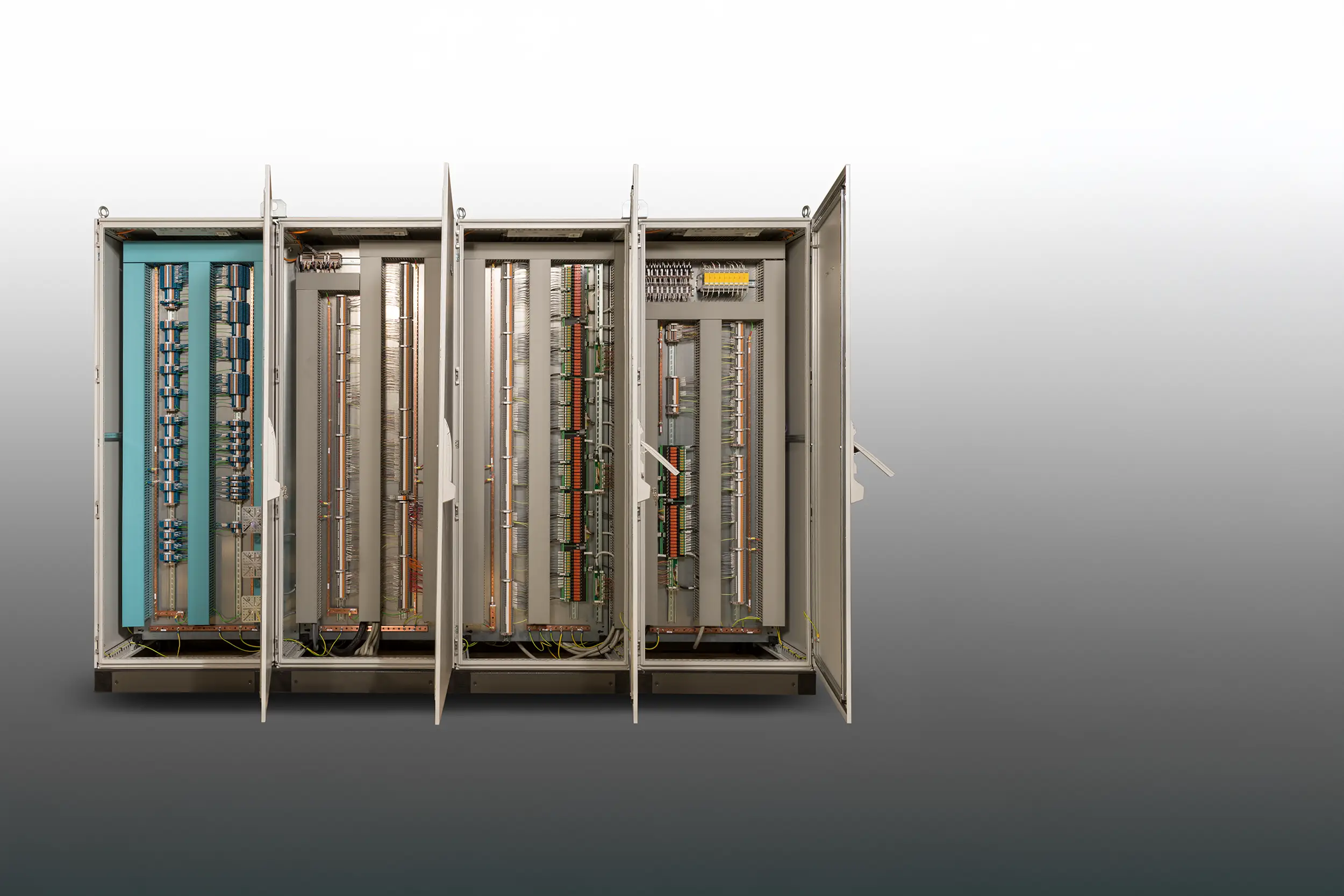

ALSYMEX designs and manufactures control command systems for the world’s most demanding sectors — oil & gas, nuclear, and defense.

With decades of experience, Alsymex delivers custom, turnkey automation solutions built for performance, safety, and reliability.

Systems are based on programmable logic controllers (PLCs), combining advanced control and monitoring tools with intuitive human–machine interfaces (HMIs) to optimize supervision and efficiency.

From design to commissioning, ALSYMEX provides fully integrated systems adapted to each client’s operational and environmental constraints.

Reference in Safety Control-Command

ALSYMEX Expertise

Clean Room Assembly Works

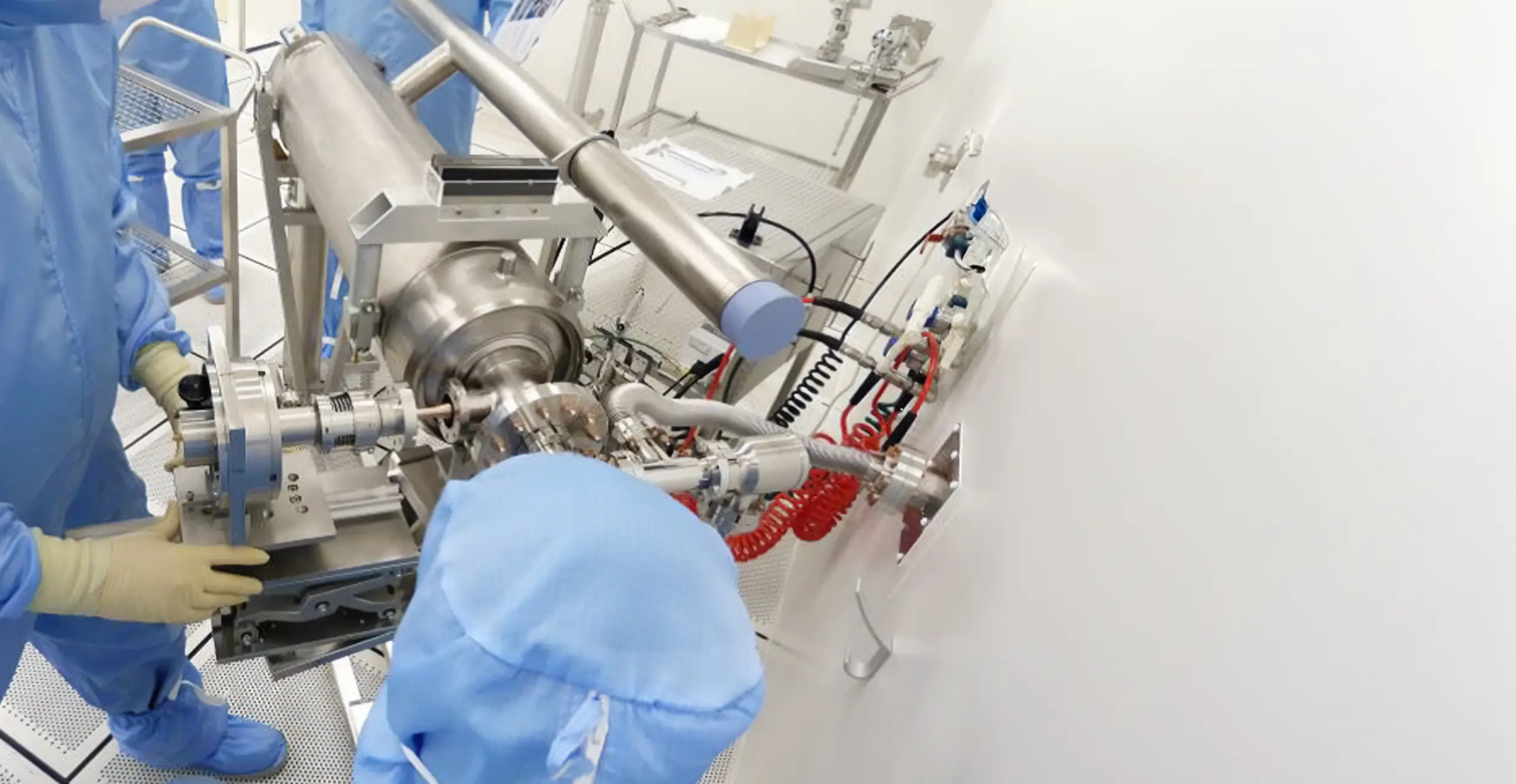

ALSYMEX is specialized in the assembly of large, multi-technology systems under the most demanding cleanliness constraints.

ALSYMEX combines technical mastery, advanced facilities, and strict quality control to ensure flawless integration — whether on client sites or within our state-of-the-art cleanrooms.

ALSYMEX’s Cleanroom Capabilities:

-

1,800 m² ISO 5 and ISO 8 cleanroom (medium scale – 3 m height)

-

600 m² ISO 8 cleanroom (large scale – 9 m height)

-

Assembly capacity: up to 10 m long, 5 m wide, and 5 m high

Advanced Assembly & Inspection Resources:

-

Immersion and spray washing systems for component decontamination

-

Dimensional and geometrical measurements using CMMs and laser trackers

-

Helium leak testing for vacuum and sealed systems

-

Optical metrology with 1,053 nm interferometers

-

Optical and electrical cabling performed under controlled environments

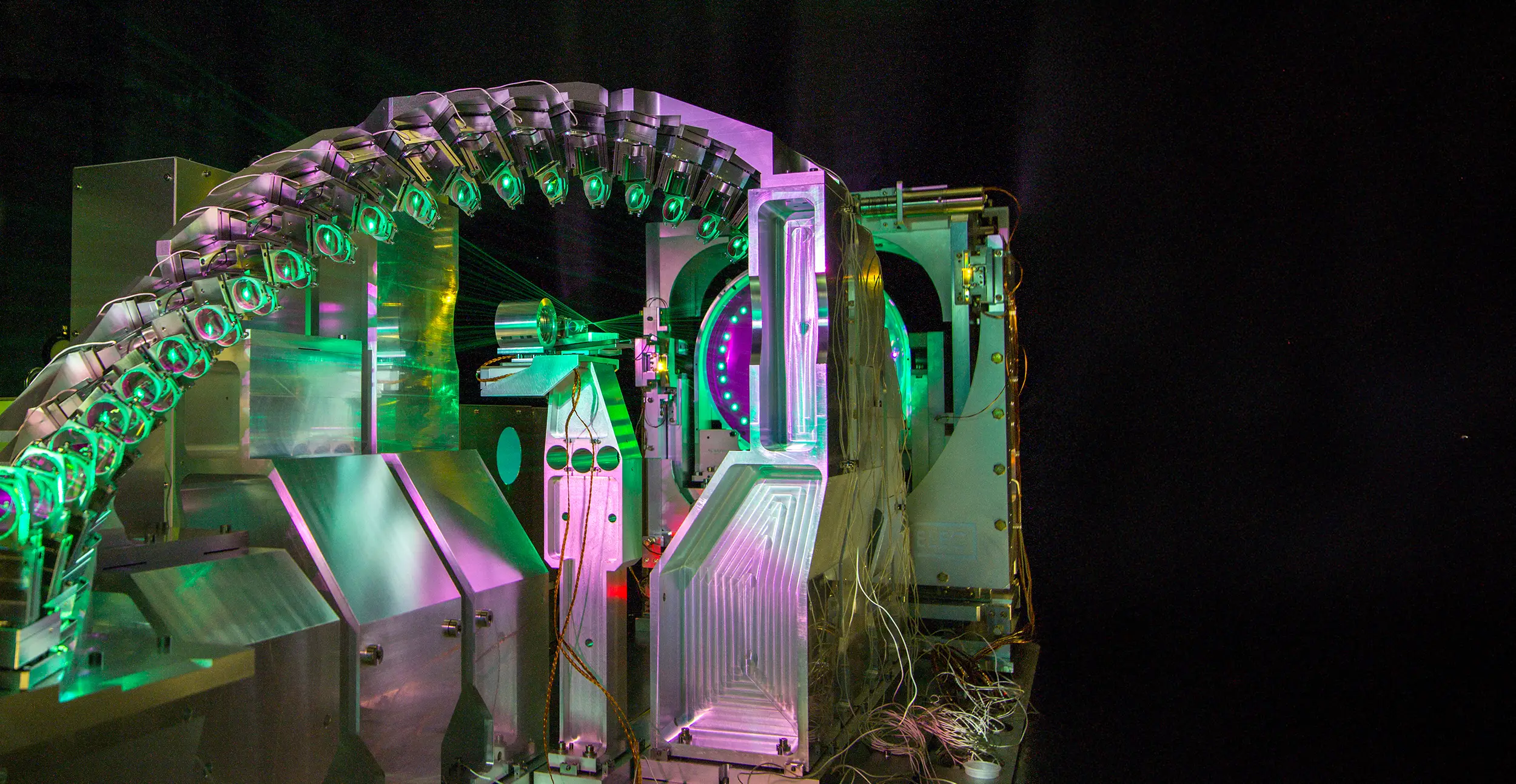

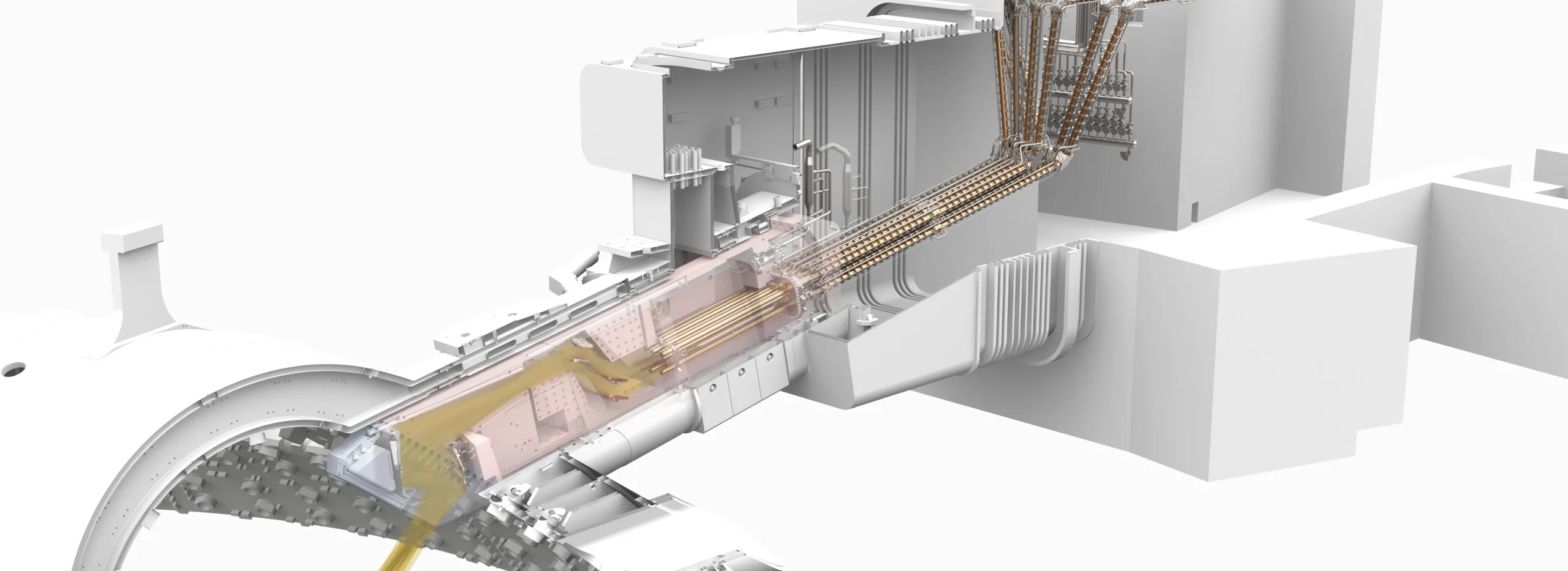

With such expertise and means, Alsymex is able to address various applications in the field of large scientific instruments, in particular high power lasers, particle accelerators and nuclear fusion experiments.

ALSYMEX has indeed developed over the years rare expertise in:

- Design, manufacturing and assembly of optical systems, including:

- Stress control induced by the mount to the optic: specific design and final measurement – thanks to interferometry measurement)

- Precise settings of optomechanical systems thanks to specific’s test benches: optic’s position up to a few microns and orientation up to a few microradians

- Optical measurement under vacuum, dry air or atmospheric pressure

- Specific optical coating development thanks to partnership with French laboratories or companies

- Design, manufacturing and assembly of optomechanical test benches: wavefront measurement, optic’s orientation/position, light’s polarization…

Reference in Clean Room Assembly Works

ALSYMEX Expertise

System Integration

Building on the experience gained in managing large multi-year and multi-technology projects and highlighting the wide range of its design, engineering and industrial capabilities and means, ALSYMEX has developed a recognized expertize in integration of complex systems.

Whenever needed, ALSYMEX may benefit from complementary skills of other companies of the ALCEN group or internationally known industrial or academic partners.

The combination of its engineering capabilities, manufacturing resources, and integration halls, including its unique complex of clean rooms, allows ALSYMEX to offer its clients in the defense, energy and research infrastructure sectors optimized turnkey solutions.